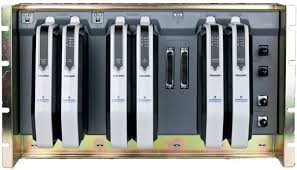

A Distributed Control System (DCS) migration is a project where some or all of a plant’s automation control equipment is replaced while introducing new technologies, functions, and features that will improve plant operations.

Is it time to Migrate Your Distributed Control System?

Operating an old DCS increases the risk of system failures, part availability, and reduced support, among other operating inefficiencies. All of these issues can lead to plant downtime, and as a result, lost revenue and safety incidents.

DCS migration not only minimizes the risks associated with having to maintain older systems but also presents the opportunity to take advantage of new technologies. With DCS migration comes more flexible operator interfaces, more open platforms, stronger cybersecurity, and better self-diagnostic capabilities, improving production throughput and reducing production and maintenance costs.

Top Reasons to Upgrade a DCS include:

- End of Life

- End of Support

- Lack of knowledge or skilled resources to support legacy systems

- Performance Issues

- Lack of openness for expansion or integration with newer systems

- Lack of features required for enhancing the control philosophies

- Maintenance Costs

Reasons to Partner with CDI Engineering Solutions:

CDI Engineering Solutions offers extensive experience with a wide range of Distributed Control Systems including Honeywell TDC and Experion, Invensys (Foxboro), Emerson Delta-V, Fisher Provox, ABB, and Moore APACS. We have delivered hundreds of successful greenfield and brownfield process control projects, both standalone and as part of a multi-disciplinary plant design projects, and dozens of successful control system modernization/migration projects.

In addition, CDI has experience with a number of PLC systems including safety related systems such as Triconex, Delta-V SIS, Siemens, SIS-Tech, Allen Bradley, Modicon, GE, and others…

Capabilities

- Instruments for Measurement and Control

- Motor & Actuator Control

- Programmable Logic Controllers

- Control Networks (Profibus, MODBUS, ASI, etc.)

- Fiber Optic Communication Systems

- Industrial Wireless Gateways

- Distributed Control Systems

- Remote I/O (CHARMS)

- Control Room Design

- Bentley Nevada Vibration Monitoring Implementation

- Annunciator Design

- Hot Cutover Coordination

- Commission Support (factory acceptance testing, site acceptance)

- Programming Support

- Plant Historian (SCADA)

- UPS Design for Critical Systems

- Alarm & Security Systems

- Premises Surveillance and CCTV